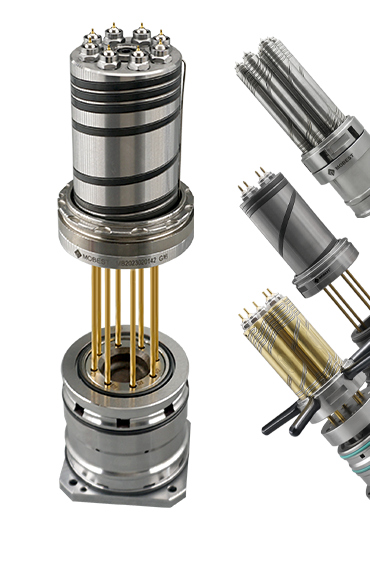

Packaging hot runner system total solution

MOBEST has extensive experience in the application of packaging hot runner systems,injection molding technology mainly includes medical packaging, cosmetic packaging, food packaging,daily necessities packaging, etc.We customize different packaging products to meet different hot runner requirements from customer.

Realize the production of 24 to 128 holes.Gate appearance on product is good.